Industrial Coffee Grinder for Bulk Brewing: A Necessary Tool

Industrial Coffee Grinder for Bulk Brewing: A Necessary Tool

Blog Article

Exactly How to Pick the Perfect Industrial Coffee Mill for Your Business

Picking the suitable industrial coffee mill for your service is a diverse choice that needs mindful consideration of numerous crucial elements. It is necessary to evaluate your particular grinding demands, consisting of the quantity of coffee refined and the desired grind consistency, as these components directly affect taste and consumer satisfaction. In addition, recognizing the various sorts of grinders available can considerably affect your functional effectiveness. As you browse these considerations, one have to likewise evaluate the effects of budget plan and maintenance. What other factors could make or damage your option?

Assess Your Grinding Needs

When choosing an industrial coffee mill, one should first evaluate their grinding requirements to guarantee optimum efficiency and uniformity. This first assessment involves comprehending the quantity of coffee to be processed daily, along with the wanted grind size for various developing methods. A high-capacity mill may be essential for companies offering large quantities of coffee, while smaller procedures might find an extra compact version enough.

In addition, it is necessary to think about the kinds of coffee beans being utilized, as different beans might call for certain grinding strategies to accomplish the very best taste profile. For circumstances, oily beans might demand a mill made to manage such features without clumping or overheating.

Specialty coffee services usually demand precise grind sizes to enhance extraction and taste, making it crucial to choose a mill that can deliver uniform results. Assessing the readily available room and electric requirements will assist in choosing a mill that fits flawlessly right into your functional process.

Understand Grinder Types

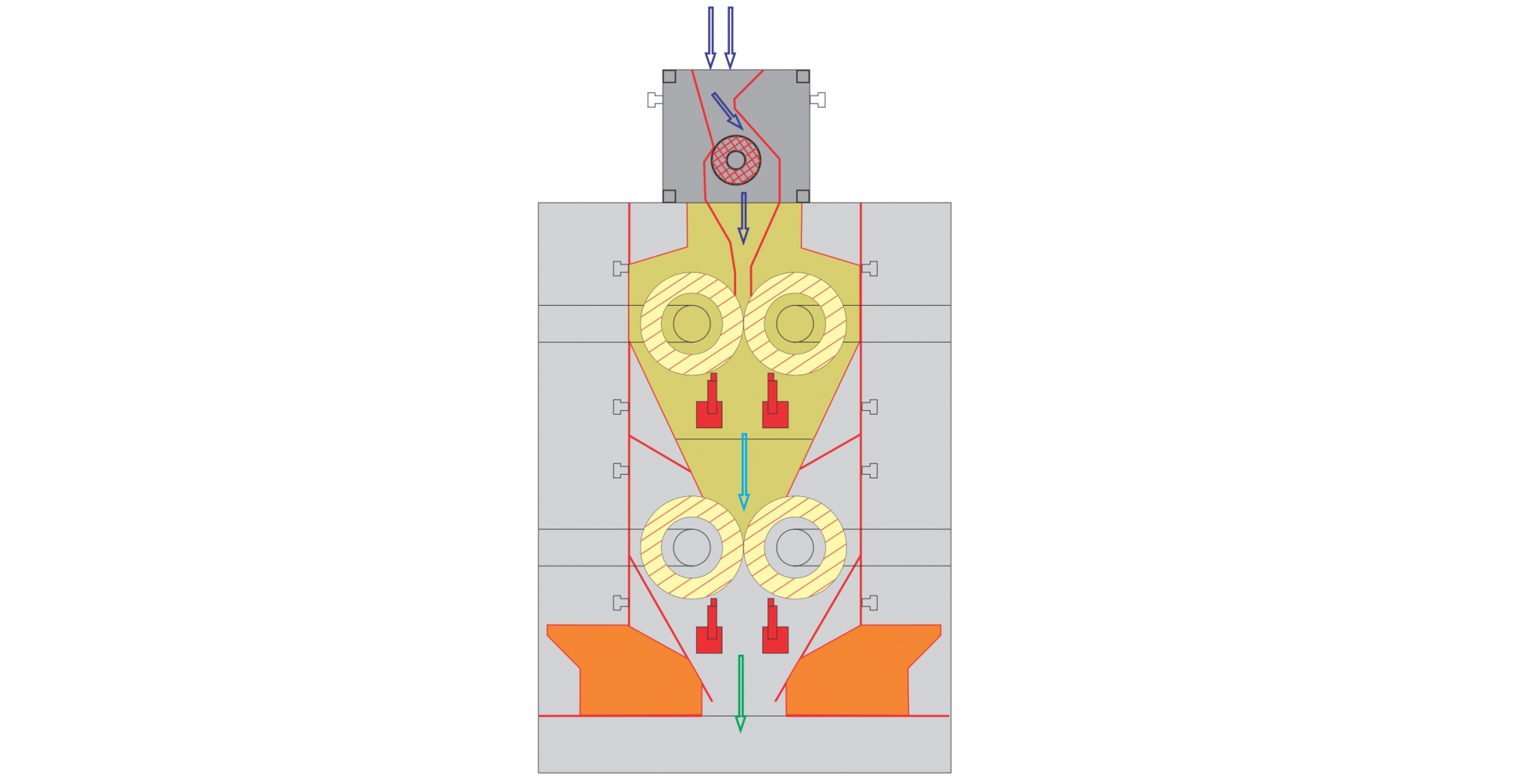

Understanding the numerous sorts of commercial coffee grinders is critical for making an informed selection that fulfills details operational requirements. There are largely 2 groups of mills: blade mills and burr grinders.

Blade grinders use spinning blades to slice the coffee beans, leading to an inconsistent work size - Industrial Coffee Grinder. While they may be more cost effective, they are usually not ideal for industrial applications where accuracy is necessary

On the various other hand, burr mills give an extra consistent work by crushing the beans in between two surface areas. They can be more classified into flat burr and cone-shaped burr mills. Flat burr grinders use a constant grind size and are typically favored for coffee preparation, while cone-shaped burr mills are versatile and can deal with a range of brew approaches, from coffee to French press.

When picking a grinder, consider the specific requirements of your business, consisting of preferred grind consistency, manufacturing quantity, and the sorts of coffee beverages you plan to supply - Industrial Coffee Grinder. Each mill kind has its restrictions and benefits, so recognizing these nuances makes it possible for notified decision-making that aligns with operational goals

Evaluate Work Dimension Consistency

Attaining work dimension uniformity is important for creating premium coffee, as variations in fragment dimension can significantly impact removal and taste. When selecting an industrial coffee mill, it is essential to examine how well the equipment keeps uniformity in grind size throughout various sets. Irregular work sizes can result in unequal extraction, resulting in a mug that might taste overly bitter or weak.

To assess grind dimension consistency, take into consideration grinders with functions such as adjustable work settings and high-quality burrs. Burr mills, in certain, succeed in producing uniform fragment sizes contrasted to blade mills. The product and shape of the burrs play a crucial function, with stainless-steel and ceramic alternatives offering resilience and accuracy.

Think About Manufacturing Ability

In the busy world of coffee manufacturing, considering production capacity is critical for organizations intending to fulfill demand without compromising quality. The production ability of an industrial coffee mill directly influences a company's ability to accomplish orders effectively, take care of supply, and reply to rising and fall market fads.

When evaluating manufacturing ability, it is important to evaluate the grinder's outcome price, generally determined in extra pounds per hour. This measurement needs to align with your business's forecasted sales volume and growth targets. A coffee shop with a high turnover may require a mill that can refine a number of hundred extra pounds daily, while a smaller sized operation may suffice with a reduced capacity model.

Additionally, take hop over to these guys into consideration the kind of coffee being refined. Different beans and blends may impact grinding rate and efficiency, demanding a grinder efficient in handling varied manufacturing needs. It's also worth considering the grinder's capacity to preserve consistent high quality under high result conditions, as any kind of changes can affect the last item.

Inevitably, choosing a mill that matches your organization's production ability will certainly guarantee you stay receptive and competitive to client assumptions.

Spending Plan and Maintenance Elements

When evaluating the appropriate commercial coffee spending plan, upkeep and mill factors play a substantial duty in the total decision-making process,. An initial investment in a top notch mill can generate lasting advantages, however it's necessary to develop a clear budget plan that straightens with your business's functional needs. Think about both the purchase rate and possible operational prices, such as energy consumption and replacement parts.

Upkeep is another essential element that can affect your spending plan. Industrial coffee grinders call for routine upkeep to ensure ideal efficiency and long life. Evaluate the manufacturer's recommendations for upkeep, including cleansing timetables and parts substitute, as these will influence long-lasting operational prices. In addition, take into consideration the availability of service and assistance, as reliable aid can minimize downtime and repair costs.

Purchasing a grinder that is why not try here sturdy yet very easy to preserve can save money gradually. While lower-priced choices might be alluring, they might sustain higher upkeep prices and decreased effectiveness. Inevitably, stabilizing initial costs with long-term maintenance and operational performance will assist you to the most effective option for your service's coffee grinding needs.

Conclusion

Selecting the excellent commercial coffee grinder necessitates an extensive examination of grinding demands, grinder types, grind size consistency, production capacity, and financial factors to consider. By focusing on these aspects, companies can ensure the procurement of a trusted, effective grinder that fulfills details functional demands. An appropriate grinder not just improves the top quality of the coffee generated however likewise adds to the general success and earnings of the business. Lasting efficiency and upkeep convenience need to remain central to the decision-making procedure.

Specialized coffee companies usually demand specific work dimensions to improve removal and taste, making it vital to choose a grinder that can provide uniform results. Apartment burr mills supply a constant grind size and are generally preferred for coffee prep work, while conelike burr grinders are versatile and can take care of a range of mixture techniques, from coffee to French press.

When picking an industrial coffee grinder, it is critical to visit homepage assess how well the device keeps uniformity in work size throughout various batches. Burr grinders, in particular, succeed in producing consistent fragment sizes compared to blade grinders.Selecting the suitable industrial coffee grinder demands a comprehensive evaluation of grinding demands, mill types, grind size consistency, production capacity, and budgetary considerations.

Report this page